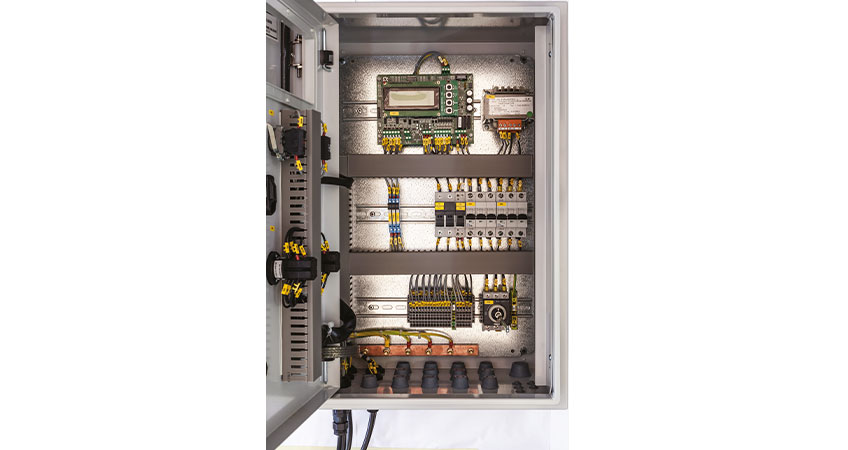

Q4E – ELECTRICAL PANEL FOR EC FANS WITH PAINT COATED METAL CASING, INTERNALLY MOUNTED CONTROLLER, PROTECTED BY AUTOMATIC SWITCHES (CIRCUIT BREAKERS) CONNECTED TO GROUPS OF FANS, FAN REGULATION CONTROL MODBUS RS485. PANEL-MOUNTED SWITCHES (1 SWITCH EVERY 2 FANS) (1X2).

Metal casing painted RAL7035, 120 micron thickness, suitable for outdoor installation

Protection class IP65

Working temperatures: -20°C/40°C

Power supply: 3~ 400V / 50Hz +PE

Main switch

Box-mounted switches (1 switch every 2 fans)

Contacts for switch status indication

Protected by automatic switches (circuit breakers) connected to groups of fans

Controller mounted inside the box

Fan speed regulation controlled by MODBUS

Free contact for unit powered indicator

Free general fan alarm contact

Warning light to signal system is powered

General alarm warning light

Quick power connectors for fans directly on panel

Quick signal connector for fans directly on panel

Execution in compliance with CE regulations

CONTROLLER Em – EC-MANAGER:

2 MODBUS RS485 connections (COM 0 on PC side & COM 1 on fan side);

Regulation mode MASTER (temperature or pressure probes) or SLAVE (0-20mA, 4-20mA, 0-5V, 0-10V);

Min. and Max. fan speed setting.

Auxiliary contacts – available contacts:

S1 – direct mode – reverse;

SP – selection of setpoints 1 or 2;

S5 – night speed limitation;

S2 – controller ON-OFF;

S6: max. spray speed enable.

3 programmable relays: RL1 – general controller alarm; RL2 – fan alarm; RL3 – relay for heat exchanger cleaning start.2 programmable analog outputs (for fan regulation or spray activation).

Advanced functions:

Emergency fan speed – fan rotation speed in the case of a control system fault (only on request);

Overspeed – possibility to increase the speed setpoint above the max. fan speed value (by-pass MAX RPM limit);

Speed-off – possibility to reduce the speed setpoint below the min. fan speed value (by-pass MIN RPM limit); Low capacity – is used to switch off groups of fans in the case of low temperatures, high temperature variations between day and night;

Anti-lock – is used to start the fans if they are supposed not to operate for a long time;

Washing – is used to program a washing cycle of the heat exchanger (start, frequency, duration), including reverse fan rotation and activation of the RL3 relay for washing system start-up;

Cleaning – is used to program a washing cycle of the heat exchanger (start, frequency, duration, rotation speed), including reverse fan rotation;

Possibility to operate the fans in reverse rotation.