Custom reference: Dry Cooler with blowing fans

Reverse forced-draught air-cooled radiators can be used to cool water or other fluids in various industrial applications: diesel and biodiesel, gas power plants, steel, chemical, food, etc.

APPLICATION

The units will be used during the plant maintenance process of some refineries in Kazakhstan.

POWER

8 Dry coolers with a capacity of 1.825kW each.

FEATURES

Dry Cooler with single cooling circuit designed and manufactured to perform at high ambient temperatures (max 60°C) with high temperature inlet fluid (100°C).

The ambient air is sucked in by the fans on the lower side of the finned pack and forced to pass through the finned heat exchanger. The air, therefore, after passing the engine, absorbs the heat from the cooling fluid preserving the fan life.

This configuration prevents the fan motor from being run over by the hot air flow leaving the exchanger, which is on the contrary the most used/adopted solution for standard liquid coolers.

The configuration, with the fan motors on the lower part of the frame, allows the replacement of the fans if necessary without having to intervene with crane systems, a safe, practical and fast solution, required by the specificity of the liquid cooler of the backup units.

BENEFITS

- Heavy duty design with high corrosion resistance

- Structure apt for crane and forklift lifting

- Special structure apt for truck transport of two stackable models

- Easily removable fan motors for coil washing and maintenance

- Excellent sound characteristics

- Easy installation

- Energy efficient – low total cost of ownership

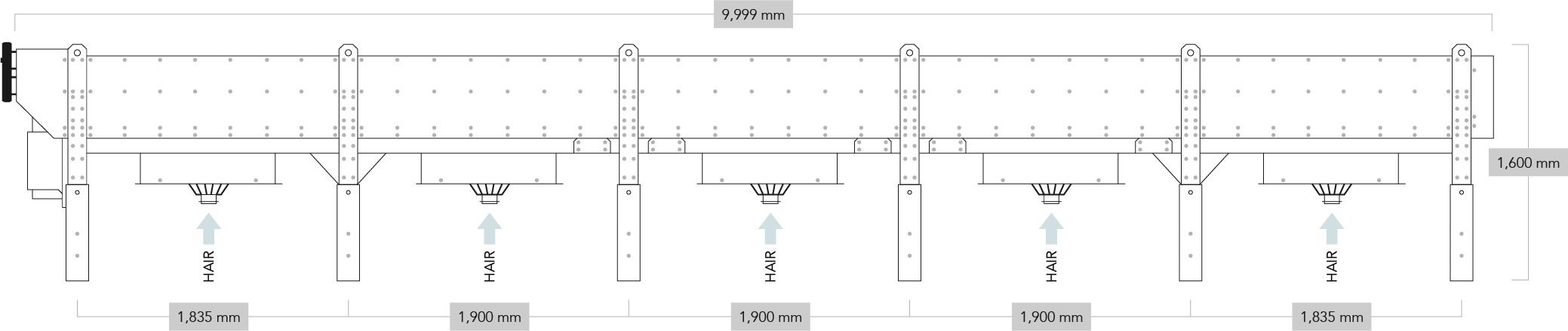

DIMENSIONS

- Height: 1,600 mm

- Lenght: 9,999 mm

MAINFRAME

Made with:

- Internal sheets in galvanized steel ZN275

- ZN 275 galvanized steel sheets painted externally in epoxy polyester

- Hot deep galvanised and painted supports

- Reinforced supports in 4 mm thick SJ375 structural steel

- Reinforced lateral bars to avoid bending during handling

- Main frame suitable for forklifts and crane lifting

- Special modular guide for forklift

- Support extensions

- Coil side protection grid

COIL

- Endplates in AlMg 5754 alloy

- Al Prepainted Hydrophobic Blue fins

- AISI316 Stainless steel tubes and headers

FAN MOTOR, WIRING AND CONTROL PANEL

- C5M protection full bell mouth painted structure

- Wired in main board (with fuses and main switches)

- Repair switch on each fan motor

- Fan motors with thermo contacts

- Cutting phase regulators 2x60A (nominal rating up to 50°C ambient temperature, derating 15A up to 60°C ambient

- Temperature (each regulator)

- Suitable up to 60°C max ambient temperature

- Control panel with heaters and integrated cooling fans

CUSTOMIZED PRODUCTS

We design customized products to meet every need; we know that specific environments require specific solutions, we are happy to help you to identify the best solution to your needs.