A solution of heat recovery and enhanced performance

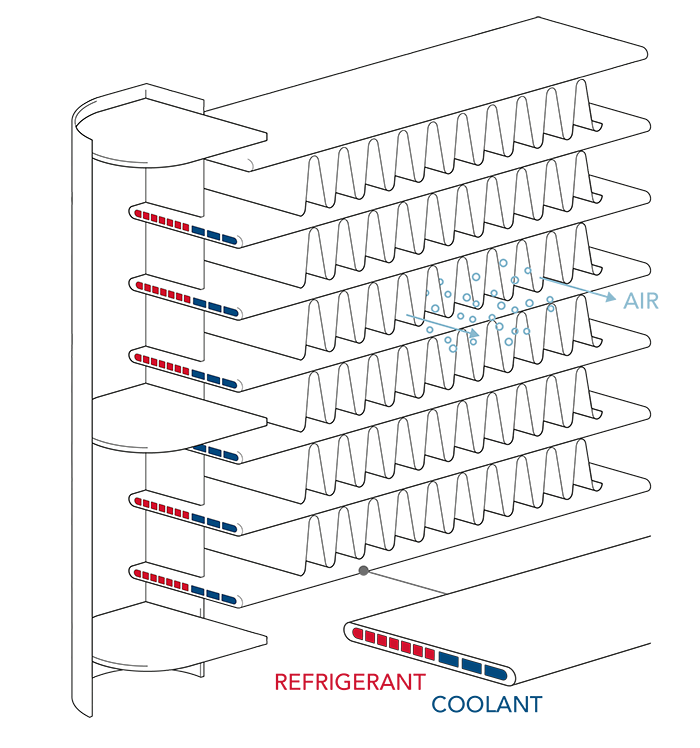

This new concept represents a revolution for heat recovery and is more than a valid alternative to conventional adiabatic systems. By using two circuits in micro-channel heat exchangers (MCHX), an additional cooler fluid can help to reduce the inlet air temperature and to recover part of the heat otherwise released completely into the atmosphere. This technology does not just enhance the performance of coolers and condensers, but also provides a warm source of heat that can be used in many applications.

Multi System Dual Flow working principle.

A valid alternative to adiabatic systems

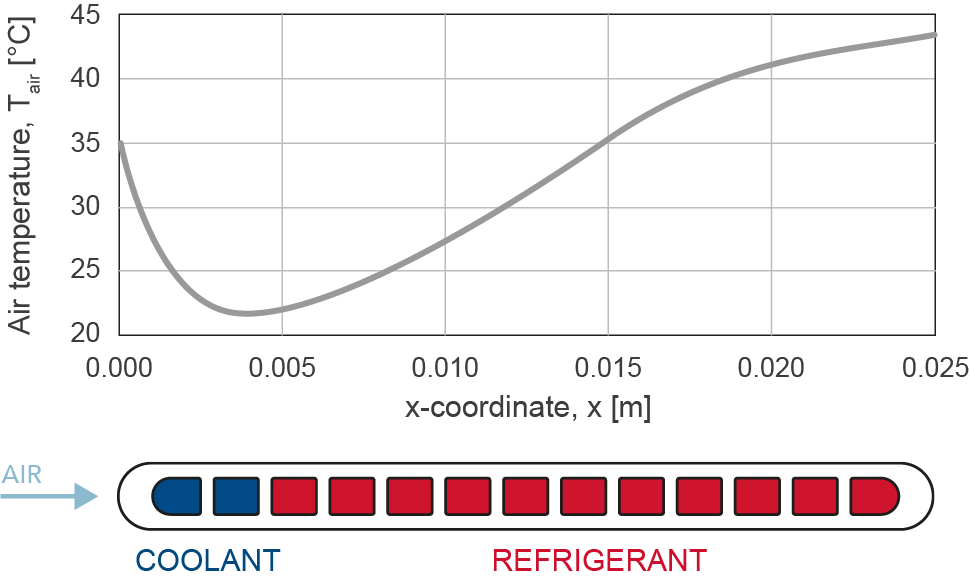

With hot weather conditions, the air that passes through the front part of the multiport is cooled down by the secondary fluid providing a heat transfer boost through the rest of the tube. Introducing water inside the tubes on a closed circuit, compared to conventional adiabatic systems, there is no water consumption and this concept is not subjected to critical hygienic conditions, water treatment, core cleaning or corrosion.

Air Temperature along the tube width.

A new solution for heat recovery, more compact and versatile

Nowadays, only in Europe, 2,860 TWh/y of heat are released into the atmosphere [1], which is almost the same amount of thermal energy used for space heating and hot water. Across the Atlantic Ocean, the US produces 43·109 GJ (11,944 TWh) of waste heat over 30°C per year [2]. As the global chiller market is expected to grow at a 3% CAGR from 2022 to 2029 [3], this number is, more likely, meant to increase in the next few years. Therefore, with the objective to tackle global warming and decarbonization, heat recovery in the field of industrial HVAC&R becomes essential.

Typically, in HVAC&R applications, plate-type heat exchangers are used upstream of condensers and coolers, introducing an additional component to the plant for heat recovery. Furthermore, in the case of condensing units, the plate heat exchanger can only extract heat in the desuperheating zone and/or it must be placed higher than the air-cooled condenser. However, these complications cease to exist with this integrated solution, more compact than air-cooled heat exchangers and more versatile than the water-cooled ones.

Reverse Carnot cycle

Calculations and tests

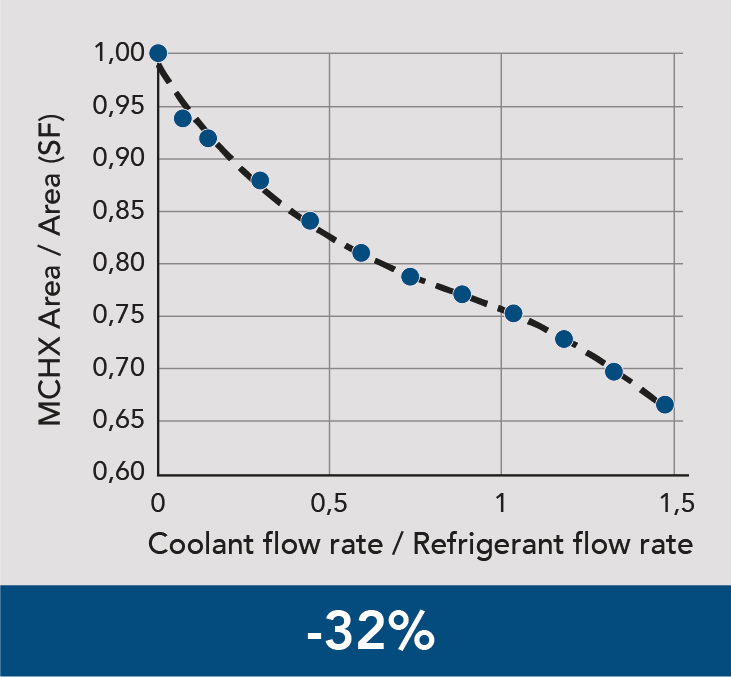

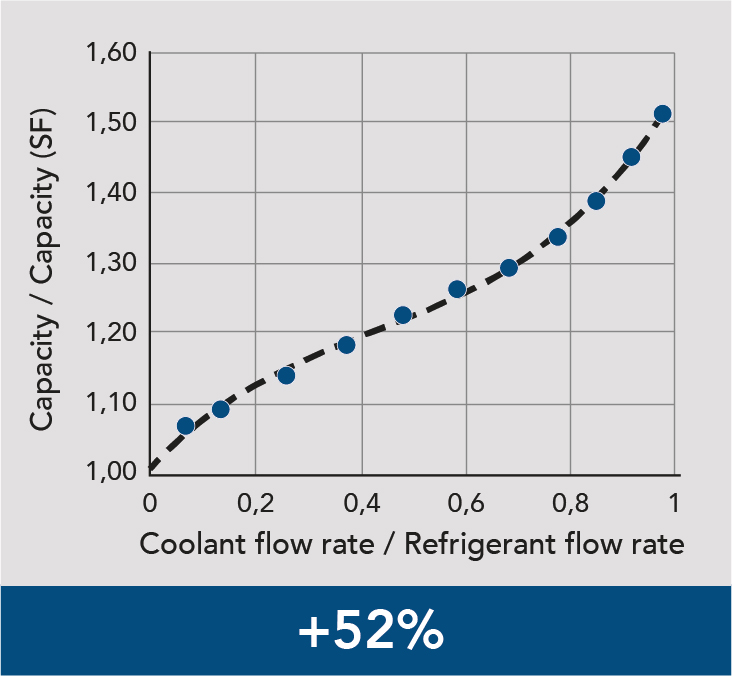

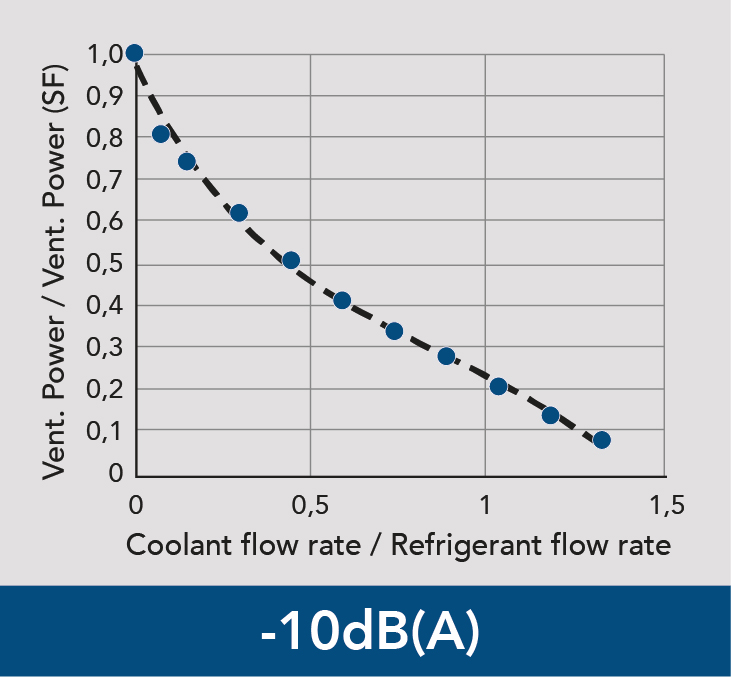

ThermoKey is able to provide accurate calculations of this device thanks to the years of studies conducted with the support of the University of Udine. Based on CFD simulations, our calculation engine is able to provide results that are in line with the experiments conducted in certified laboratories. The analysis shows that, depending on the working conditions, the capacity can increase by more than 50%, which can allow us to reduce the required units or the exchanger size by 32%. Besides, the ventilation power can be reduced and the related noise by 10 dB(A).

Size / Weight reduction

Capacity increase / Numb. of units reduction

Vent. Power reduction / Noise reduction

Tests have been performed in other two different laboratories showing the following results:

- the first test was conducted at constant condensing temperature constant and showed a higher capacity by 51%;

- the second one was performed for constant capacity or to improve the performance of a chiller by dropping by 5K the condensing temperature.

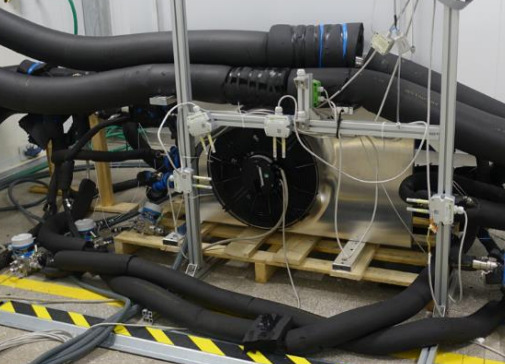

Test facility of Eurac Research heat pump laboratory

Application

Process cooling, refrigeration and data centers always require cooling power during the year whereas chillers mainly operate during the hot seasons for which simultaneous need of cold and warm is required. The technology of MSDF allows flexibility and fine tuning of the operation point depending on the requirements.

While waiting for new polices to connect these machines for heat recovery to offices and residential areas, refrigeration represents the most important application of this product. Indeed, thermal energy is needed to defrost evaporators, and MSDF condensing units are able to provide a warm coolant which is mostly free from expenses.

Please forward us a request with your use case conditions and we will help you providing the best solution to your needs.

sales@thermokey.com or your reference area manager

This patented technology of Multi System Dual Flow, also world-wide patent pending, is supported by a structured portfolio of IP rights.

References

- D. Connolly, . B. V. Mathiesen, P. A. Østergaar, B. Möller, S. Nielsen, H. Lund, U. Persson, S. Werner, J. Grözinger, T. Boermans, M. Bosquet and D. Trier, “Heat Roadmap Europe 2: Second Pre-Study for the EU27,” Department of Development and Sustainable Energy Planning Research Group, Aalborg University, 2013.

- A. S. Rattner and S. Garimella, “Energy harvesting, reuse and upgrade to reduce primary energy usage in the USA,” Energy, vol. 36, no. 10, pp. 6172-6183, 2011.

- Exactitude Consultancy, “Chillers Market by Type, Power Range, and End User and Region, Global trends and forecast from 2022 to 2029,” 2022.