ThermoKey will participate in the Green Cooling Summit virtual showroom to be held on 25 – 27 May 2021.

Green Cooling Summit 2021

The virtual summit addresses political and technical approaches to manage the HFC phase-down under the Kigali Amendment with natural refrigerants, and it is jointly organized by the German Environment Agency and Deutsche Gesellschaft für Internationale Zusammenarbeit on behalf of the Federal Ministry for the Environment, Nature Conservation and Nuclear Safety.

Our experts will be present at our virtual showroom to guide you through ThermoKey's solutions for sustainable cooling

Natural refrigerants to reduce global warming and respect the atmospheric ozone layer

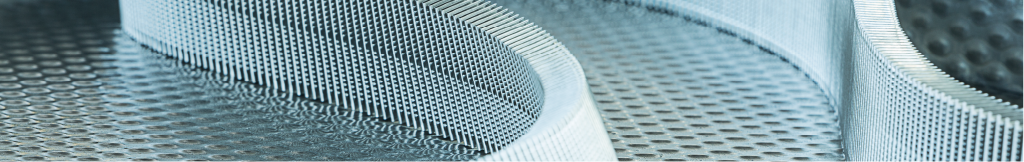

TKMicro - Microchannel unit

With the use of these units it is possible to save up to ¾ of the refrigerant charge compared to the traditional Tube and Fin technology, reducing the refrigerant charge of any refrigerant circuit, the costs and risks connected throughout the entire plant life cycle.

The microchannel units are compatible with all traditional HFC refrigerants, the new HFO and natural refrigerants (propane and ammonia) and with water, up to a maximum operating pressure of 45 bar.

Stainless steel exchangers

Stainless steel exchangers (tubes, fins, casing) for the use of ammonia (ODP and GWP equal to zero). Thanks to its efficiency, it is one of the most environmental friendly refrigerant.

ThermoKey stainless steel exchangers can be made with either certified pipes and AISI 304 or AISI 316L casing.

The finned pack of the stainless steel tube coils can be in AISI 316L, Aluminium Magnesium, Aluminium, Hydrophobic Blue and Double Layer black or other coatings depending on the environment of use.

The quality of a stainless steel coil passes through the quality of its materials and its welding, which must be done:

- using generators and semi-automatic orbital TIG welding torches – to guarantee quality and repetitiveness of the process;

- with welding (argon) in controlled atmosphere – both externally and internally the circuit – to avoid oxidation;

- with “butt” welding without tube-return bends or tube-manifold interstices. No dirt and no risk of ice formation between the tube and the return bends with the consequent risk of loss.

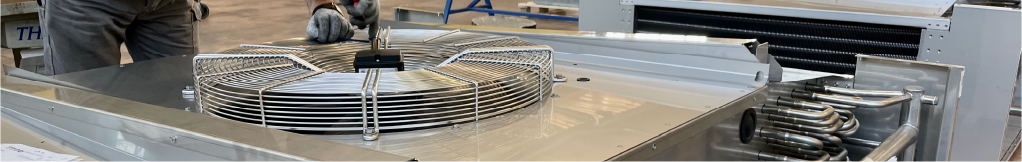

Unit coolers

Unit coolers for CO2 use (ODP and GWP 0 and 1 respectively).

Amongst the most important factors to be taken into consideration, there are the values that CO2 presents for GWP and ODP indicators, respectively equal to 1 and 0, which demonstrate its energy efficiency and sustainability from an environmental point of view. ThermoKey has already achieved these standards and continues to work to ensure the highest efficiency of units with the lowest environmental impact.