Sweets Production Poland

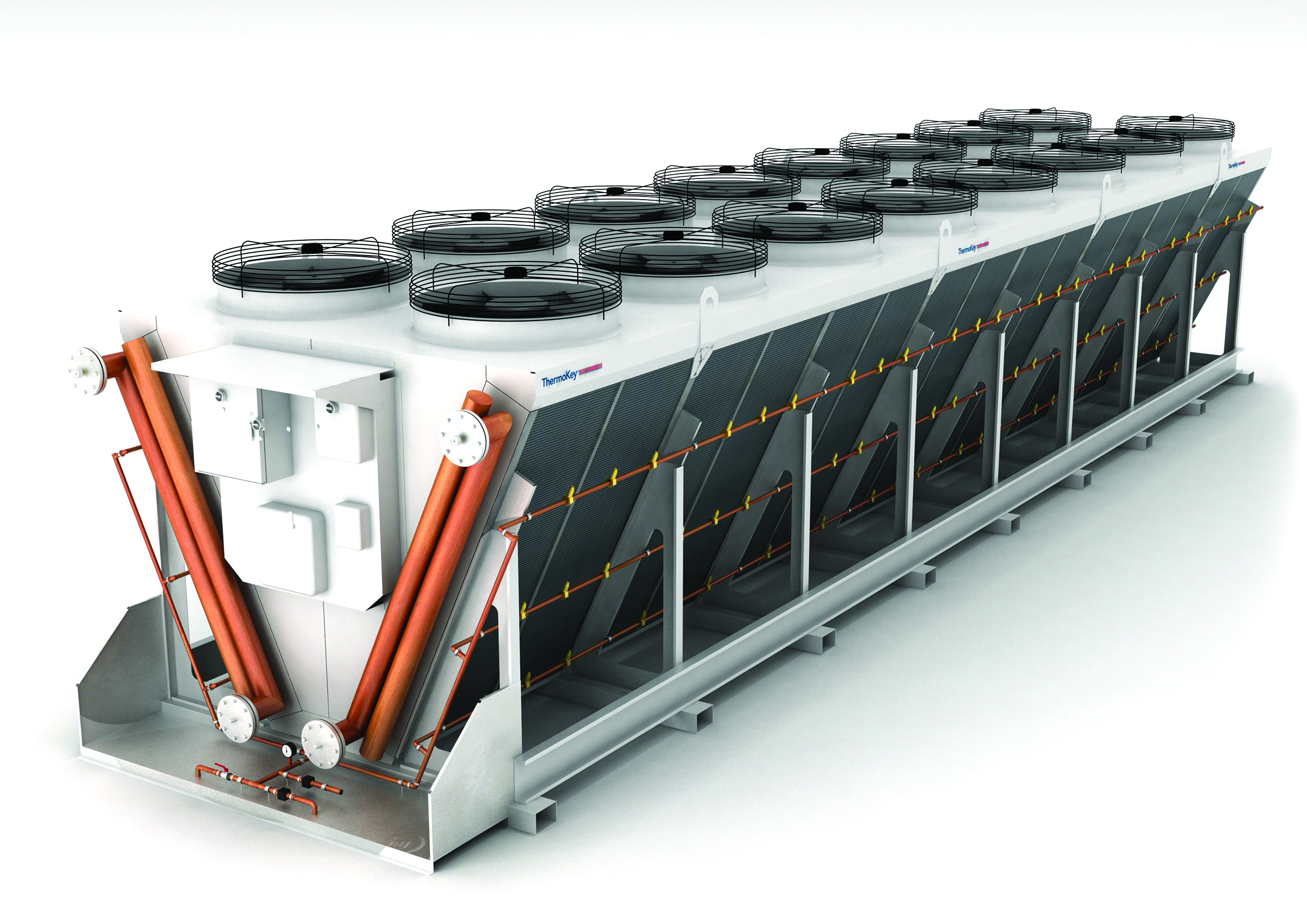

Six dry-coolers, model JGH2790.C5 / 03Q2EAF (EC) (AFS) S, capacity 466 kW each, supplied for a new plant in Poland of a world leading company in the production of exclusive sweets.

In order to optimise costs of absorbed power, units are equipped with EC fans. High efficient adiabatic system (AFS) ensures safety even in case of the highest region ambient temperatures.

Adiabatic system - AFS (Air Fresh System)

Sweets Production Poland

ThermoKey adiabatic cooling system equipped with special high-pressure nozzles, which allows to compensate the peaks of power to be dissipated, with minimum water consumption for a maximum of 500 hours per year.

The combination of high pressure water, the nebulization effect of nozzles (MISTING effect) and a specially designed electronic control system represent the innovative principle of AFS system.

It uses only the quantity of water necessary to obtain the desired adiabatic effect.

Tüv Certificated: “No danger in correlation with the risk of legionnaires’ disease”.