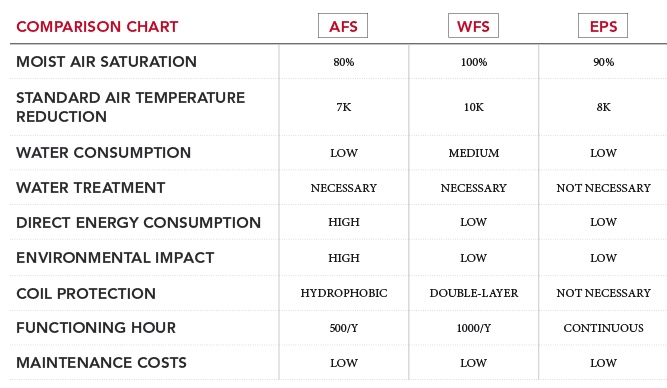

The adiabatic system applied to Dry Coolers and large remote condensers are activated in order to increase the air relative humidity that passes through the heat exchanger in order to reduce the temperature and increase the heat exchange.

The physical principle is that of the latent heat of evaporation: whilst evaporating the water absorbs heat from the air entering in the heat exchanger and lowering its temperature.

ThermoKey has developed different adiabatic systems to be effective and efficient under certain environmental conditions.

It is therefore essential to use the most correct system in relation to the installation needs.

The most important parameters to take into consideration when choosing the correct adiabatic systems are:

- Possible working hours per year.

- Obtainable relative humidity gap (efficiency).

- Obtainable saturation.

- Maximum difference of dry bulb temperature between ambient air temperature and suction air temperature after the adiabatic cooling.

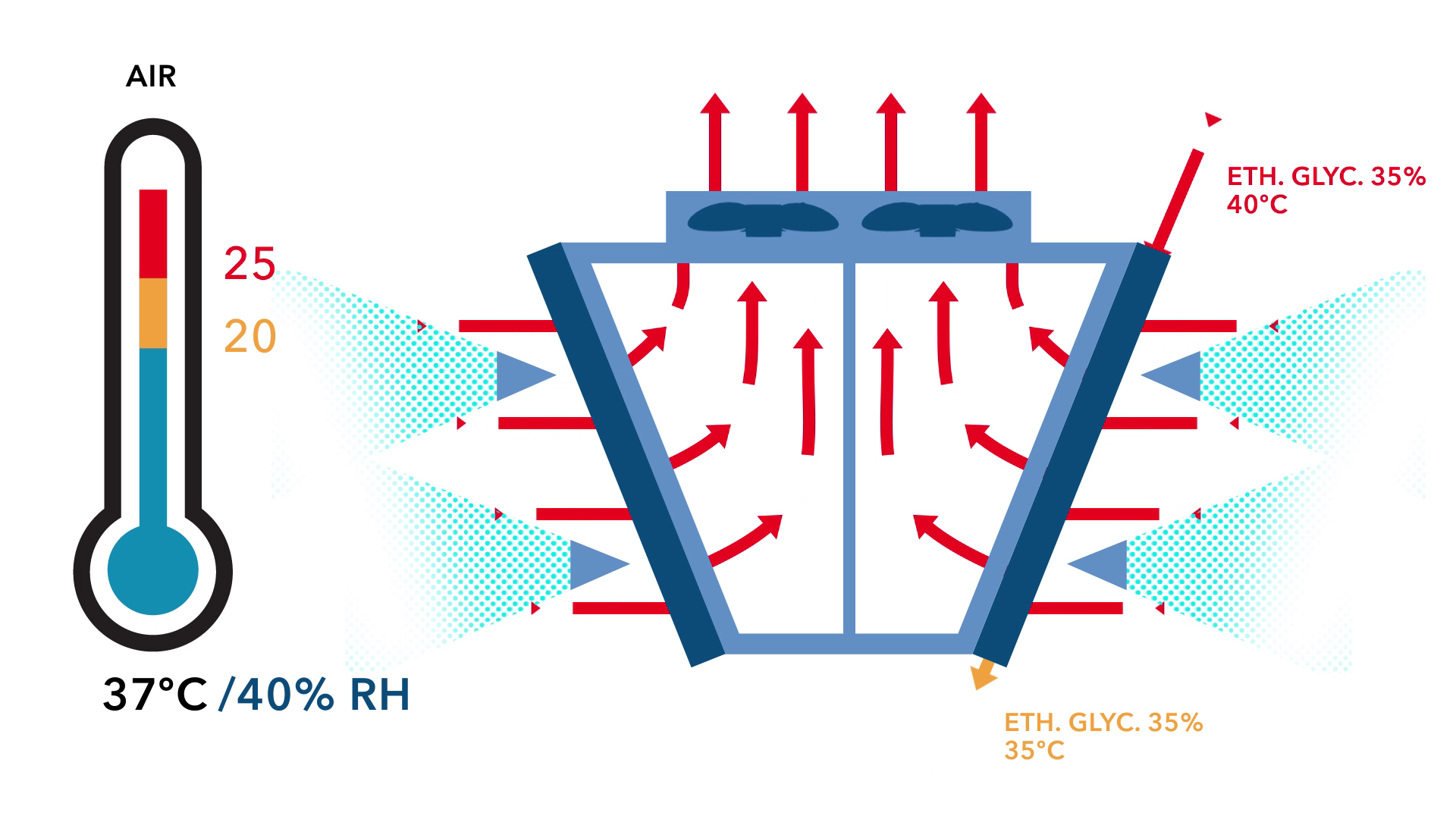

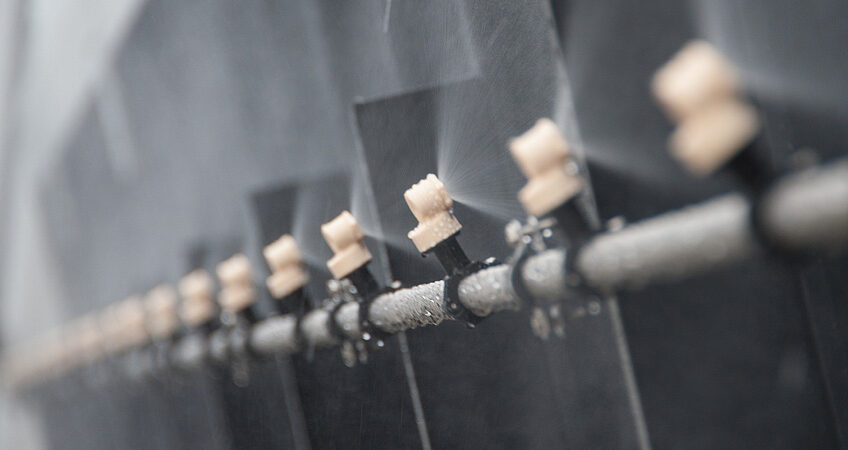

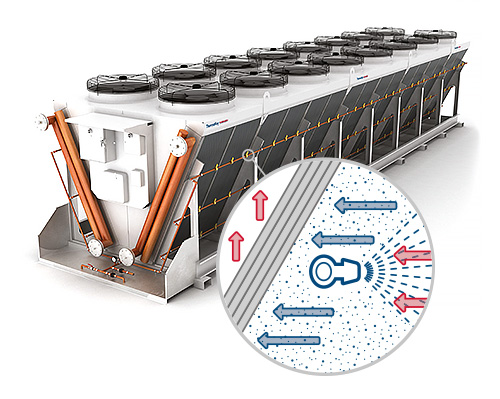

ThermoKey adiabatic cooling system equipped with special high-pressure nozzles, which allows to compensate the peaks of power to be dissipated, with minimum water consumption for a maximum of 500 hours per year.

The combination of high pressure water, the nebulization effect of nozzles (MISTING effect) and a specially designed electronic control system represent the innovative principle of AFS system.

It uses only the quantity of water necessary to obtain the desired adiabatic effect.

Tüv Certificated: “No danger in correlation with the risk of legionnaires’ disease”.

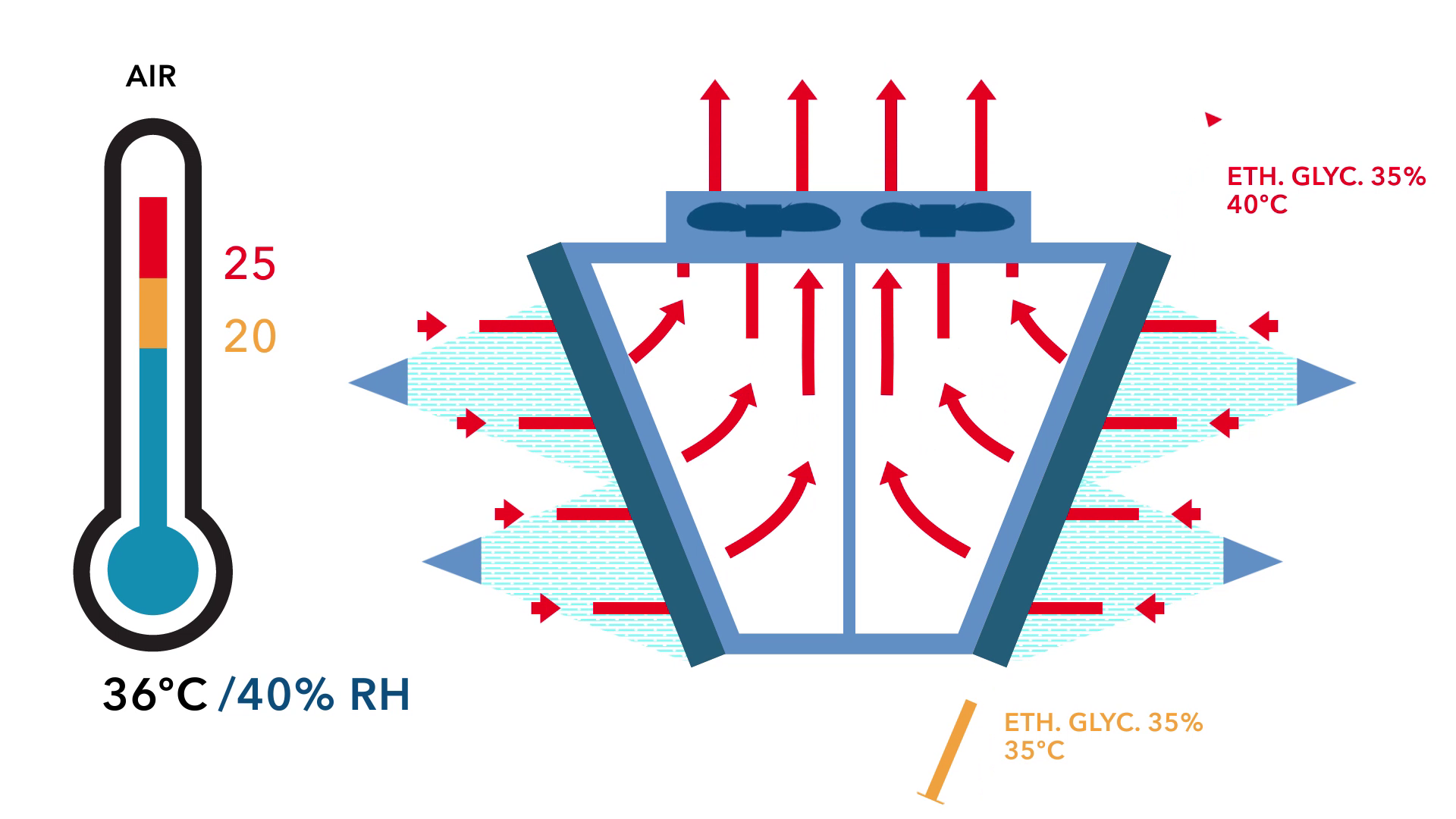

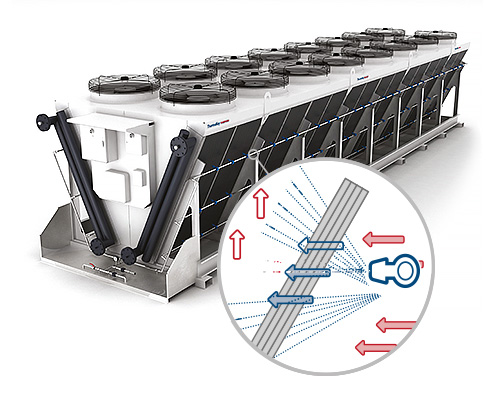

It is ThermoKey hybrid cooling system which allows a complete flexibility of operation, working at low pressure (2-3 bars) and for a very high number of hours per year (up to 1000).

The user can choose whether to prioritize the consumption of water or electricity. Thanks to the misting effect and to the increased exchange efficiency, the WFS system allows to reach higher saturation levels.

Since WFS systems use water for a high number of hours per year, a black double-layer fin is provided in order to improve the protection of the finned pack.

Mainz Universitätsmedizin Laboratory certifies that the WFS meets the standard VDI 2047 part 2 securing hygienically sound operation.

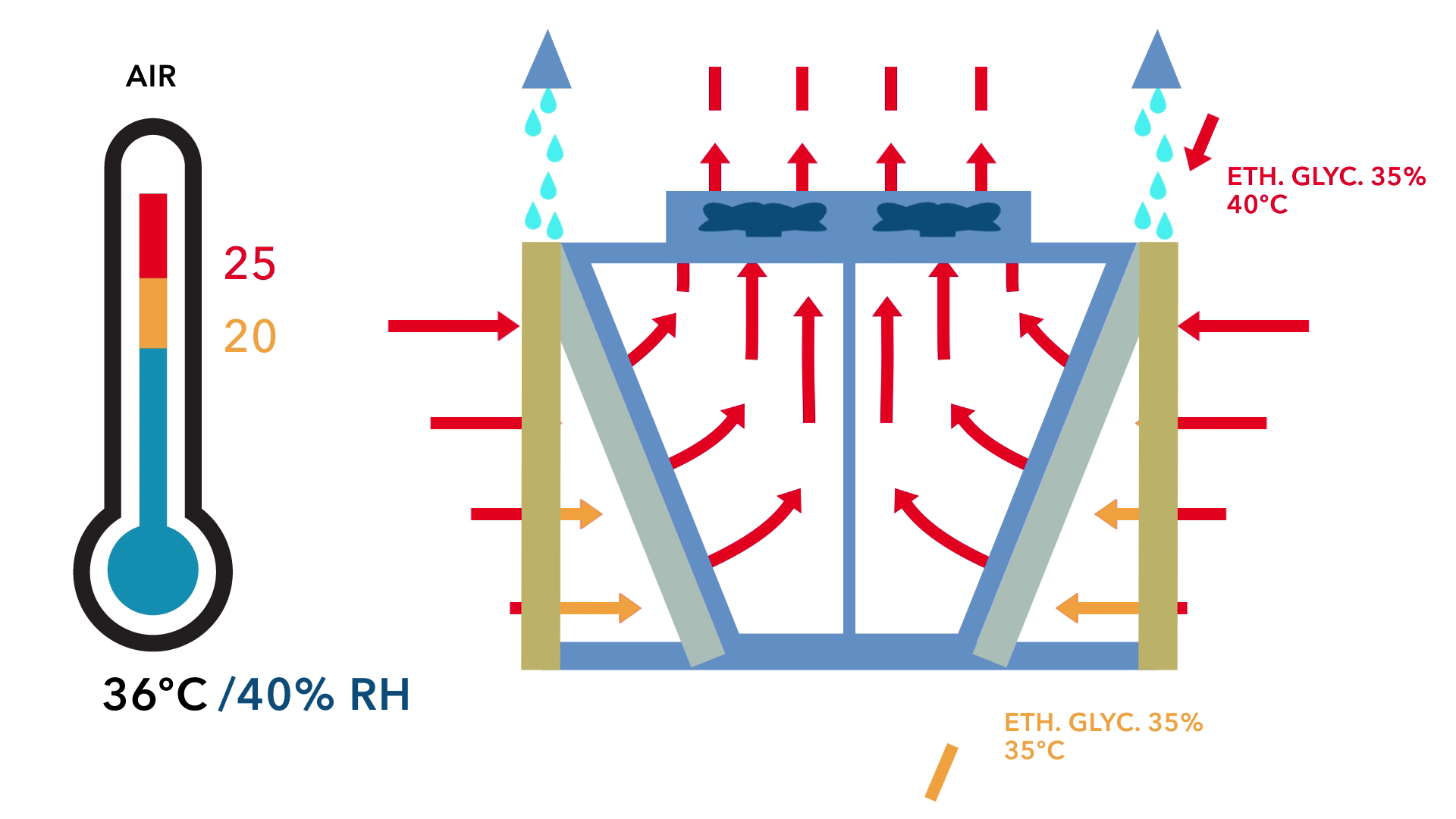

The evaporative panel system completes ThermoKey’s offer in adiabatic cooling. Thanks to a homogeneous and adjustable distribution of water on the panels this system allows to reach a high saturation level and therefore an efficient capacity increase with low water consumption (hours per year unlimited).

EPS has been designed for seasonal working cycles without any specific time limitation and can be completely disassembled for cleaning and maintenance operations.

Thanks to the evaporation contained in the panel there is no need of any protective treatment for the heat exchanger. It is possible to use the water distributed by the common water supply network.

To guarantee the highest quality and safety of its products, ThermoKey has had its EPS system (Adiabatic Evaporative Panel System) certified by an independent institution.

The hygienic certificate refers to VDI 2047-2 which takes into consideration the requirements set by the law and by industry standards in the main countries of use of the specific product.